Data-based inspiration for product design with Altair’s solidThinking Inspire

Where do your designs begin? Do you use previous projects as your launchpad, or can you rely entirely on hard-earned knowledge of structural engineering theories? When solving straightforward problems, designers tap into what we call their “engineering intuition” to build efficient structures. But when a structural system involves a complex hodgepodge of concepts, designs and materials, that intuition may not be enough.

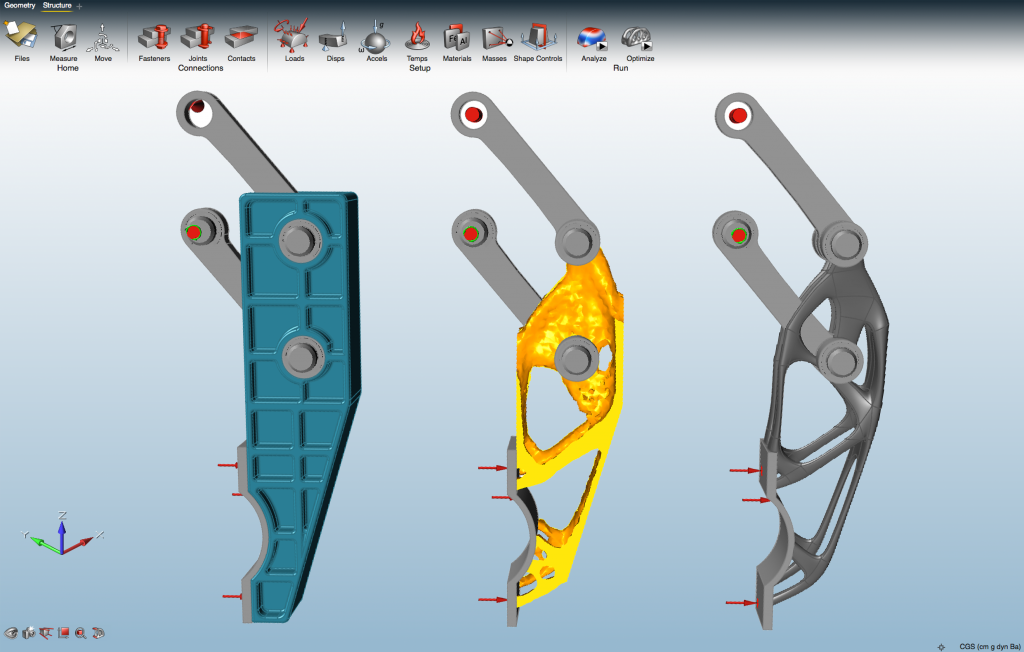

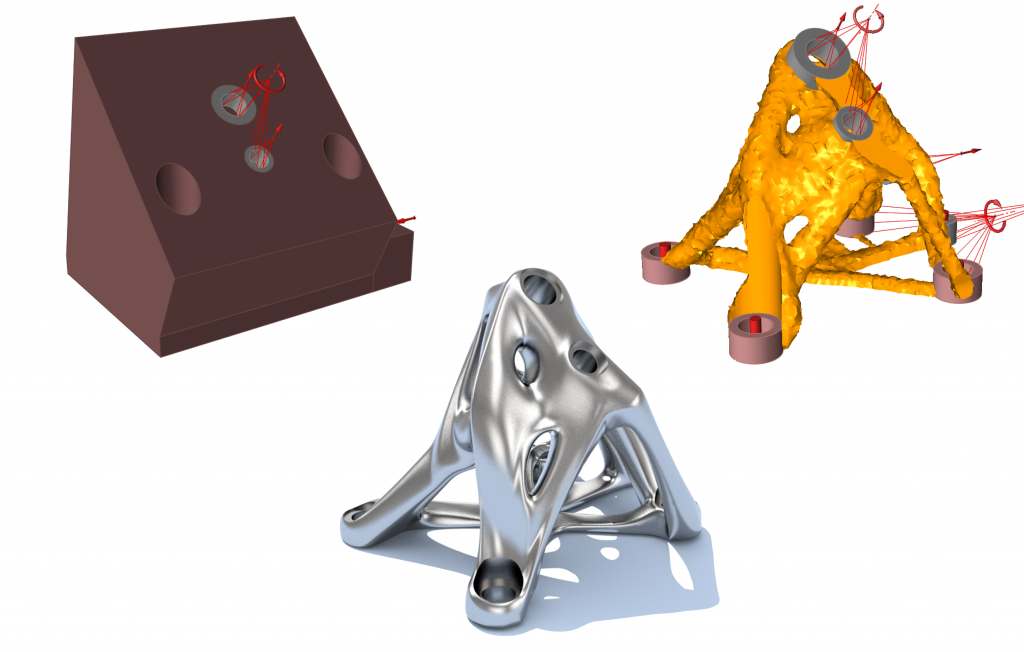

Here’s where Altair’s solidThinking Inspire software comes into play. Built upon algorithms that were developed by biomedical research for predicting human bone growth, solidThinking Inspire is a platform for early-stage optimization and analysis or verification of designs. It uses a ‘Topology Optimization’ algorithm to generate product designs in 3D and using topography optimization can change the shape of shell structures through stamped bead patterns.

When used in the earliest stages of the design process, solidThinking Inspire users can reduce design time, increase product performance, and efficiency while also reducing the mass of the product parts – making them lighter and easier to produce. Design engineers, product designers, and architects are able to freely design and try out concepts to determine if they are structurally sound without having to build physical prototypes, which can be time-consuming and costly.

Navistar, a U.S. manufacturer of large vehicles and engines, uses solidThinking Inspire to design and improve its products. Martin W. Dirker, a technical specialist at Navistar, said: “Reducing part and assembly mass is important to us and Inspire shows us how we can do this while also increasing the durability of structural components.

“The great thing is the rapid feedback from design to an optimized shape,” he added.

The latest release of solidThinking Inspire 2017 includes several ground-breaking new features, including a new Motion tool that allows for easy mechanization of moving parts; updated Partition Tools for dividing parts into design and non-design regions; and a Bolt Pretension tool to help users achieve more accurate results. Combined with the option to evaluate early feasibility based on manufacturing processes like Casting, Sheet Metal Stamping, Extrusion, Injection Molding, Forging, 3D Printing via quick simulation or early definition of relevant manufacturing constraints, solidThinking Inspire can help every design engineer reduce expensive iterations on design projects.

The solution changes the way product designers and structural engineers approach design. It enhances human creativity by proposing forms that can be evolved into a finished product with easy export to your preferred CAD tool and 3D Printing or additive layer manufacturing (ALM).

Companies that use solidThinking Inspire can achieve reduced design timelines, material usage, and costs and optimal designs can be determined very early in the process, and allow users to be more confident about their designs.

For more information on solidThinking Inspire and case studies on Design for ALM, visit web.solidthinking.com.

READ MORE

- The criticality of endpoint management in cybersecurity and operations

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications

- How Japan balances AI-driven opportunities with cybersecurity needs

- Deploying SASE: Benchmarking your approach

- Insurance everywhere all at once: the digital transformation of the APAC insurance industry