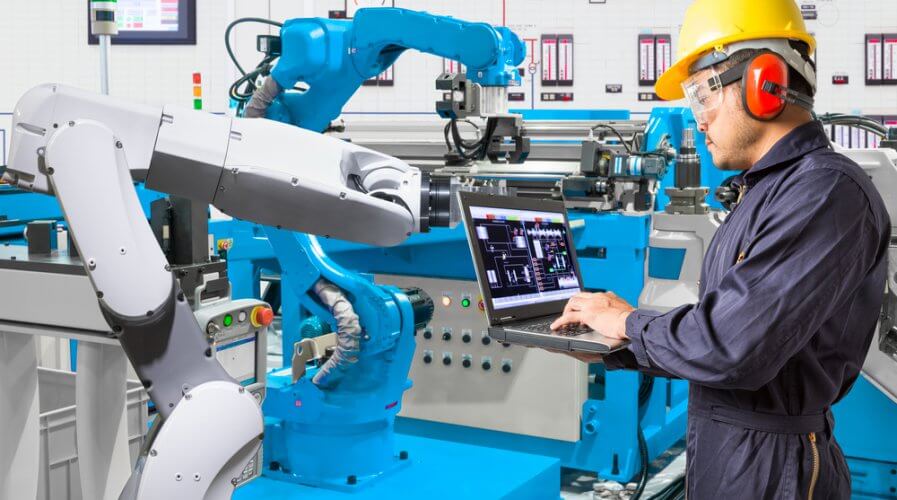

What will the future of manufacturing look like? Source: Shutterstock

Can IoT help manufacturers adopt the servitization model?

WHEN manufacturers develop the capabilities to provide services and solutions to supplement their products, they transform their business to adopt the servitization model.

In an increasingly complex world, manufacturers find that transforming into service providers can offer many advantages.

Servitization allows manufacturers to bundle their product with a core service – which further deepens and strengthens the relationship with the customer.

It also helps bring in additional revenues to bolster the company’s finances and improves customer retention rates by creating significant value with its redefined offering.

However, from the very beginning, servitization has been a model reserved for manufacturers of high-tech equipment.

Rolls Royce, for example, launched the TotalCare program sometime in the 1990s. It bundled aircraft engines with optimization and maintenance services in a pay-per-use type of offering where customers paid for “(engine) power by the hour”. The program has been a roaring success since inception.

For a customer’s point of view, if manufacturers use servitization offer the product and service as a bundled offering, then they benefit since they only incur a small(er) charge to use the product which would otherwise take serious capital investment — to procure and maintain.

On the other hand, if servitization induces the manufacturer to simply offer services as an add-on subscription, then customers benefit as they’re able to optimize the use and maintenance of the product.

What’s driving servitization?

While the term servitization was coined sometime in the 1980s, up until a couple of years ago, manufacturers didn’t leverage new-age digital technologies to re-think how they expand their portfolio of offerings to include services.

In fact, aside from high-tech equipment manufacturers, nobody else cared much about the model.

Consumer durables, for example, or manufacturing of plumbing devices such as water pumps didn’t see how servitization could help them, given the low cost of acquisition, repair, and replacement of their products.

However, using the Internet of Thing (IoT), big data analytics, and artificial intelligence can create a lot of exciting opportunities for manufacturers.

It is these technologies that helped make servitization an option for more manufacturers, not just those that deal with high-tech industrial equipment.

Using sensors embedded into products, manufacturers can monitor the use of their products while customers have deployed them on the field.

In a connected environment, this data can be tracked and analyzed in real-time, to ensure customers receive the support they need – when they need it most.

Several businesses are already adapting to the servitization model. Be it Caterpillar, Airbus, Siemens, MAN Trucking, ThyssenKrupp Elevators, or BASF Chemicals, everyone is using IoT to turn their business around and provide better products and services to customers.

Technology is the reason why manufacturers are the new service providers, and the revolution isn’t limited by industry segment. Whether you manufacture coffee machines or copy machines, consider how servitization and IoT can help you earn a competitive edge over the competition.

READ MORE

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications

- How Japan balances AI-driven opportunities with cybersecurity needs

- Deploying SASE: Benchmarking your approach

- Insurance everywhere all at once: the digital transformation of the APAC insurance industry

- Google parent Alphabet eyes HubSpot: A potential acquisition shaping the future of CRM