Upgrading from Industry 4.0 to Industry 5.0 is important. Source: Shutterstock

Frost: How industry 4.0 pioneers can evolve to the industry 5.0 model

BUSINESS leaders pursuing the digital transformation agenda have been trying to adopt the industry 4.0 model to unlock efficiencies using technology.

Pioneers that have climbed the digital maturity curve to succeed with digital in the industrial environment do have an edge in the market against competitors. However, they cannot afford to rest on their laurels.

Given the pace of change, Frost believes that leaders in the industrial space need to start thinking about industry 5.0, which it believes should be dubbed ‘the era of experience’.

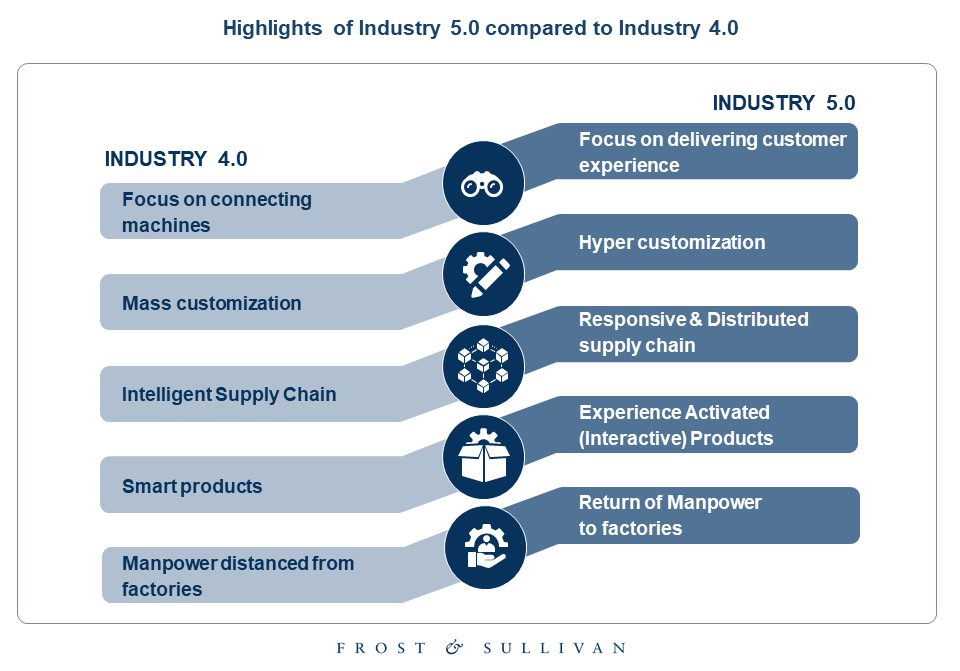

To be clear, there are a few significant differences between industry 4.0 and industry 5.0.

Industry 4.0 focused on connecting machines, enabled mass customization, led to the creation of intelligent supply chains, facilitated the development of smart products, and distanced manpower from automated factories.

On the other hand, industry 5.0 is intent on delivering better customer experiences through hyper customization, responsive and distributed supply chains, experience activated products, and the return of digitally-empowered humans to the shop floor.

“At the core of this concept are new business scenarios aided by advanced technology themes, focused on delivering individually tailored customer experiences. The individual definition of products, services, and solutions will fuse into one and create Industry 5.0,” said Frost & Sullivan Global Managing Partner Aroop Zutshi.

The advanced technology themes that Zutushi is referring to include:

- Industrial blockchain

- Drones

- Exoskeletons

- Additive technology (3D printing)

- 5G and beyond (including 6G)

- Mixed reality

One of the interesting components of industry 5.0 is ‘hyper customization’. According to the firm, each individual product will be unique to its intended customer and manufactured accordingly.

To cater to the trend of “batch size one,” manufacturers will have large, robotized intelligent factories positioned around the globe to manufacture the basic design of the product in bulk.

The basic, semi-finished material will then be sent to local factories, where the final stages of the product will be completed using manual labor.

Zutushi’s firm believes that this style of distributed supply chain coupled with the gig economy will transform the existing nature of jobs, and industries will experience it firsthand.

Further, the return of ‘digitally-empowered’ in the industry 5.0 setting is interesting because it implies that workers will need plenty of training to handle new-age tasks in the new-age industrial environment.

“While the explosion of data will create new employment opportunities associated with data monitoring and control, job roles on the shop floor will evolve and integrate multiple skill sets into one. Roles such as machine maintenance and quality assurance will merge into plant operations and become one job.”

Overall, Frost & Sullivan believes that industry 5.0 is a model of the next level of industrialization. Businesses that have made progress towards industry 4.0 must start looking at how they can evolve. After all, technology will continue to disrupt unless harnessed effectively.

READ MORE

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications

- How Japan balances AI-driven opportunities with cybersecurity needs

- Deploying SASE: Benchmarking your approach

- Insurance everywhere all at once: the digital transformation of the APAC insurance industry

- Google parent Alphabet eyes HubSpot: A potential acquisition shaping the future of CRM