(Photo by Robyn Beck / AFP)

Can cobots transform the agriculture industry?

Robots in agriculture are becoming increasingly used by the industry today. An example would be the multiple analytics and machine learning tools used in smart farming to help with predicting harvests. One of these tools, agriculture robots, are normally used collaboratively (known as cobots). These robots possess mechanical arms and make harvesting much easier for farmers.

Compared to traditional industrial robots and machinery, cobots are designed to work alongside human employees, giving manufacturers the benefits of both robots and humans combined. While the automotive sector has been using it for some time, especially on the assembly line, other industries are now finding more use cases for cobots as well.

Previously, cobots could only do simple tasks on the assembly line like spray painting and assembling cars. Now, with IoT features like heat sensors and thermal cameras built-in, cobots are able to perform more accurate tasks based on their use case.

It is important to note that cobots are not meant to replace the human workforce totally. Some tasks may be sped up, but the main purpose of cobots is to enhance productivity and provide insights for decision-making. While cobots can perform longer and increase productivity, human intervention is still needed in monitoring these machines.

Cobots still have limitations when it comes to tasks that require more finesse. They are unable to replace humans in every operation as they are mostly limited to tasks requiring basic cognition. This is why cobots need to be built with sensors that can scan, recognize and carry out their given tasks.

At the same time, cobots do help solve the issue of staff shortage in certain sectors. For example in agriculture, cobots are used for harvesting as its harder to find manual labor to do such jobs these days.

Today, living in the era of robotic technologies and automation fosters a heightening interest in agri-tech. Cobots remain the fastest-growing segment of industrial automation, projected to grow at a CAGR of 43.4% from 2021 to 2027.

However, with the constant rise of cobot usage, existing government initiatives, and farmers demanding perfect “man-machine” collaboration in urban farming, cobots will continue to make dramatic inroads in the agriculture landscape.

For non-agriculturally intensive nations like Singapore, food security is a concern, further exacerbated by the COVID-19 pandemic. Within Singapore’s small, but growing urban agriculture sector, there exist food growers like Singrow. Singrow develops innovative agri-tech solutions for producing fruits and vegetables, and deploy cobots in their harvesting and pollination systems. Collaborating with Universal Robots and Augmentus, Singrow uses an integrated AI model that helps to identify flowers and strawberries.

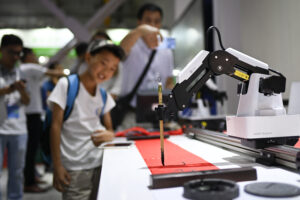

(Photo by WANG Zhao / AFP)

Once the flowers are identified by the camera on the cobot, a fan gets activated to blow faster for more effective pollination. Singrow matches strawberries to its database using its camera and infrared scanner and programs the cobot to pick out ripe strawberries.

According to James McKew, Regional Director of Asia-Pacific in Universal Robots, modern agriculture more automation will be seen soon in urban farming.

“Typically, agriculture-related jobs demand a soft touch to handle delicate flowers and fruits. Similar tasks that require high precision and concentration may be a challenge for humans after a prolonged period. In order to reduce human errors and maintain a high production output, cobots will be a perfect solution for urban farming. Repetitive tasks such as manual pollination can be taken over by cobots, relieving human workers to take on better roles that tap on their cognitive and social abilities,” explained McKew.

In the past, McKew pointed out that farmers were resistant to advanced technologies such as automation and robotics and they typically prefer traditional methods instead. Most farmers believed that robots in agriculture are expensive to purchase, inflexible, space-hogging, and require engineers to program the robots.

“As people often associated cobots with traditional industrial robots, we need to address these misconceptions. Today’s cobots are versatile and flexible, they are adaptable to urban farming purposes. These small-sized cobots are not only cost-effective, but their simple programming also makes them ideal for a wide range of applications in the agricultural landscape. Farmers need not worry about the unintuitive programming of robots since cobots are easy to implement, operate and maintain,” he added.

Cobots and SMEs

In fact, Singapore has introduced an initiative to set aside S$60 million for a new Agri-Food Cluster Transformation Fund (ACT) under its Budget 2021 measures. Replacing the Agriculture Productivity Fund (APF) in 2020, the local government and Singapore Food Agency aims to support the agri-food sector in increasing their productivity and meeting Singapore’s goal of producing 30 percent of its nutritional needs through local farms by 2030.

“With such initiatives, the government is actively encouraging farmers to adopt automation for improved productivity and financial gains. As more cobots are introduced in the agricultural landscape moving forward, the education of robotics technology will become more prevalent than before,” said McKew.

Apart from robots in agriculture, SMEs are also now realizing the potential of cobots. While the complexity and costs of managing robots in the past may have been a concern for them, cobots are now a game-changer for SMEs.

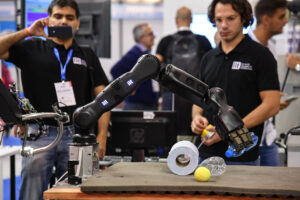

(Photo by Andreas SOLARO / AFP)

For example, with a lack of large floor space being a problem in Singapore, SMEs are turning to cobots as they are designed to work near human workers, addressing safety concerns in factories. Cobots are lightweight, flexible, and easy to deploy for multiple operations, making them a boon for SMEs.

“Even employees without robotic experience or backgrounds will be able to operate a cobot. The cobots give SMEs the advantages of advanced robotic automation with none of the traditional added costs associated with robot programming or set-up,” said McKew.

Singapore-based SME Sky Engineering was initially facing challenges due to rising wages, space constraints, towering real estate prices, and safety issues.

After they deployed cobots, the SME found that they had the luxury of having one man tend two machines. The company was pleased with the return on investment as cost reductions meant a payback period of only 15 months.

Other use-cases of cobots include Singapore’s Nanyang Technology University (NTU) use of eXtremeDisinfection roBOT (XDBOT), a disinfection robot that performs deep cleaning without involving human contact during the COVID-19 outbreak.

In Taiwan, cobots are seen in non-traditional settings such as coffee dripping and cocktail preparation in cafés. For instance, Babo Arms, a bubble tea shop located in Taiwan introduced a UR5 cobot to make tea, clean cups, seal drinks and even handling drinks to customers.

Cobots and 5G

With enterprise 5G in the horizon in most parts of Southeast Asia, cobots will only be able to improve their performances. Not only will the high speed network improve latency issues with these machines, 5G will also enable them to be fully automated and perform tasks with greater accuracy.

According to Sarmad Nafees, Strategic Product Manager at Ericson, “while cobots may be the next big thing in the industry, human-robot-collaboration requires application driver quality of service to minimize risks during the performance of critical tasks.”

Ericsson, Hitachi and Georgia Tech created a solution that aims to increase productivity for cobots by allowing the human operator to share the workload. Ericsson’s 5G core network is configured via a remote-control client application to ensure the interaction between the robot and human operator is safe, and the robot follows real-time guidance.

As robots in agriculture and other industries continue to see increased adoption, businesses also need to ensure they are aware of the security risks of agritech. While most of these cobots may have some security features built in them, they are still capable of being compromised by cybercriminals if sufficient cybersecurity protection is not in place.

At the end of the day, it’s not just about maximizing productivity and efficiency with cobots, but also ensuring these machines are well protected to avoid any disruption in production.

READ MORE

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications

- How Japan balances AI-driven opportunities with cybersecurity needs

- Deploying SASE: Benchmarking your approach

- Insurance everywhere all at once: the digital transformation of the APAC insurance industry

- Google parent Alphabet eyes HubSpot: A potential acquisition shaping the future of CRM