(Source – Swisslog)

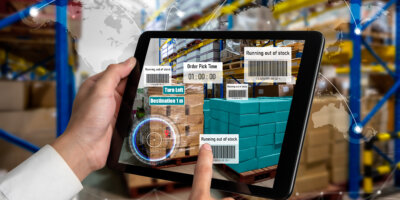

The rise of the warehouse robots

When it comes to warehouse technology, robotics and automated machinery are the most common technologies being implemented today. Mordor Intelligence expects the warehouse robotics market to reach US$23.09 billion by 2027. The market was valued at US$9.88 billion in 2021.

Part of the growth is caused by the emergence of the Industrial Internet of Things (IIoT) and networks of connected systems that help industries perform tasks like material batching, picking, ordering, packaging, warehouse security, and inspection. Together, these can improve operational efficiency by huge margins.

Advances in technology and developments in the field are enabling many machines to be automated, with minimal human intervention needed. While the logistics industry is expected to benefit most from these automata, other industries are also seeing use cases where specifically developed automated systems could take on many tasks.

During the recent SEMICON Southeast Asia 2023 expo in Penang, there was a large section of the expo floor dedicated to warehouse technology. From robotic arms to automated guided vehicles, here are the top five types of warehouse technology that businesses might look to implement:

- Automated Guided Vehicles (AGVs): Mobile robots that navigate through the warehouse using different guidance systems such as magnetic tape, markers, or laser sensors. They transport goods, pallets, or bins from one location to another, eliminating the need for manual transportation and reducing labor costs.

- Autonomous Mobile Robots (AMRs): AMRs are intelligent robots equipped with sensors and cameras that allow them to navigate the warehouse environment safely. They can handle tasks like picking, sorting, packing, and replenishing inventory. AMRs are versatile and can adapt to changing layouts and workflows, making them well-suited for dynamic warehouse environments.

- Robotic Arms: Robotic arms or collaborative robots (cobots) are used for tasks that require dexterity and precision, such as picking and placing items on shelves, palletizing, or packing. These robots are capable of performing repetitive tasks quickly and accurately.

- Automated Storage and Retrieval Systems (AS/RS): AS/RS systems are designed to efficiently store and retrieve goods in a warehouse. They typically consist of a combination of robotic cranes or shuttles that can move vertically and horizontally along aisles to access and retrieve items. AS/RS systems maximize space utilization, minimize errors, and speed up the storage and retrieval process.

- Warehouse Management Systems (WMS): WMS software plays a crucial role in coordinating and controlling all robotic operations in a warehouse. These systems manage inventory, track orders, optimize workflows, and communicate with the robots to ensure efficient operation and coordination between different tasks.

With the demand for warehouse technology increasing, there have also been numerous startups and enterprises offering hardware, software and consultation services. SwissLog, for example, delivers data-driven robotic solutions for logistics automation.

According to Sky Lee, sales manager at SwissLog Malaysia, the company’s AutoStore, an ASRS, allows businesses to store more products in the same footprint by stacking bins up to a level of 7.5m. Robot workers bring stock item bins to a human operator’s workstation. The workstations are universal, capable of inbound, outbound, and cycle counting processes.

Designed for housing small parts such as semiconductors or electrical components, Swisslog’s AutoStore’s solution uses a novel design to enables direct stacking of bins on top of each other and storage of multiple Stock Keeping Units (SKUs) in a single bin. Over time, the system performs natural slotting where products with a higher rotation are stored on the top layer to ensure faster picking time

“Any industry can benefit from AutoStore as a technology. We initially thought the AutoStore would be more suitable for the retail and e-commerce industry. However, we discovered that also more useful in the semiconductor and hardware industries. There is now more usage in recent years,” explained Lee.

Another example is Dell Technologies, which offers solutions around predictive maintenance, OEE, yield optimization, asset utilization, and more.

Randeep Kapur, Chief Technology Officer and Field Director for Global Industries, Asia Pacific, Japan and China at Dell Technologies feels that organizations are embracing a new wave in implementing technology. He agrees that AI may be about to change everything, but edge computing and 5G are the core technologies most enterprises are looking at to improve their productivity.

“There are three components businesses need to look to when it comes to using technology. The first is ensuring the right technology is used for the right proportion and to the right limit. Secondly, they need to understand where it is going to be used from a business point of view. They will want to optimize or digitalize a business process or orchestrate the business process workflows. You need to be very clear on how you’re going to display your business unit. And the component is about the people who are going to work with the technology. For example, we are able to make the machine stop working when it senses an employee is not wearing safety gear. So it’s up to us to manage how and to what level we need to digitalize things,” said Kapur.

READ MORE

- Strategies for Democratizing GenAI

- The criticality of endpoint management in cybersecurity and operations

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications

- How Japan balances AI-driven opportunities with cybersecurity needs

- Deploying SASE: Benchmarking your approach