The Robotic Revolution in Fulfilment That’s Opening Opportunities

Most professionals in the warehousing and distribution sectors would agree that 2021 is shaping up to be both highly challenging for the business, yet it’s also a time of enormous opportunity.

There has been a widespread uptake of online retail shopping, with delivery, logistics and fulfilment operations in consequently much-increased demand. Opportunities are coming despite some labour shortages and increased property prices — the combination presents challenges that need solutions.

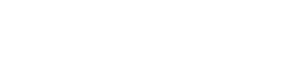

Yet the basic figures show how demand for logistics peaked as the effects of COVID took hold, with the prevalence of “delivery” in Google search terms skyrocketing:

Source: OECD

There are also the ever-present issues of supply chain management in terms of keeping quality control standards high, reducing spoilage and waste, and ensuring employee safety. Today’s supply chain companies are perhaps not able to respond as they should to their customers’ newly-changing demands. According to EY, 67% of Asia-Pacific respondents to the global consultant company’s survey stated they are taking steps to change supply chains – compared to 52% of global respondents.

The presence of technology in the supply chain is beginning to create significant rewards for those providers capable of integrating internal systems with those of their partners: sharing near-real-time information regarding stock levels, for example, creates much more responsive and efficient operations.

Source: Geek+

On the warehouse and distribution centre floor, in the loading bays and picking stations, robotics and automation are technologies that are creating significant gains for operations in many organisations. Leading supplier of AI-driven automation systems, Geek+ is helping businesses improve operator efficiency and reduce picking errors, plus, it’s not uncommon for its customers to be able to free up 30% of total warehouse space during initial deployment. Freeing up resources lets businesses explore new partnerships or markets, pass on savings to customers and reduce the pressure on recruitment.

Over time the smart systems produce more efficient and streamlined processes that can adapt quickly to peaks in demand, market fluctuations and changes in business strategies.

Automation across Grocery & E-Commerce

The Circle K retail operation in Hong Kong comprises 300 branches, supplied by a 150,000 ft2 warehouse that the company decided to automate, transforming its operations with 100 Geek+ AMRs (autonomous mobile robots), to ensure the effective daily handling of over 1,000,000 products.

Using robots helped alleviate significant staff shortages, and allowed them to move heavy pallets (bottled drink loads can top 600kg in a single load) quickly and safely — work that previously had to be done manually.

The warehouse automation robots from Geek+ allowed the company to effectively add a third to the usable storage capacity in a single facility, with pickers able to remain at a single station, with goods brought to them by automated systems.

Inventory tracking from inbound to outbound goods is now achieved in software. The algorithms can position popular items closer to employee stations, cutting down wasted time moving around the facility. As demand changes, so too does the storage shelf arrangement.

Source: Geek+

Smart automated robots have also enabled UK retail giant Asda (part of Walmart) to offer a greater capacity to support the increasingly popular omnichannel retail habits of its customers. Its parcel collection and returns business, Asda toyou serves over 100 retail brands’ sales and returns.

Since the global move towards e-commerce ordering and convenient return options, many retailers are adopting automated systems to help them cope with the increased complexities involved in omnichannel — Asda toyou is a case in point.

The benefits to the Asda business were tangible almost immediately. Jon Parry, Vice President of Asda Logistics Services (ALS), said, “The robots work alongside our colleagues, enabling us to drive greater efficiencies at times of peak demand, which have helped to boost the number of parcels we’re now able to sort through our Asda toyou service.”

Source: Geek+

Proving the Business Case for Automation

Today’s smart robotic technologies allow warehouse operations to take place more safely and efficiently, faster, and in a significantly smaller space. Many operations directors are embarking on trials and proofs of concept of robotic and related technologies, and seeing for themselves the effects: among them, resources freed up and less pressure to keep staff levels at optimum.

Geek+ offers pre-production in-place prototyping of its robotic solutions and demonstrations of its productivity-boosting backend software. To take advantage of the opportunities granted to the sector by the heightened demand for facilities and speed of fulfilment (without the pain points), get in touch with a representative from the company near you today.

READ MORE

- 3 Steps to Successfully Automate Copilot for Microsoft 365 Implementation

- Trustworthy AI – the Promise of Enterprise-Friendly Generative Machine Learning with Dell and NVIDIA

- Strategies for Democratizing GenAI

- The criticality of endpoint management in cybersecurity and operations

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications