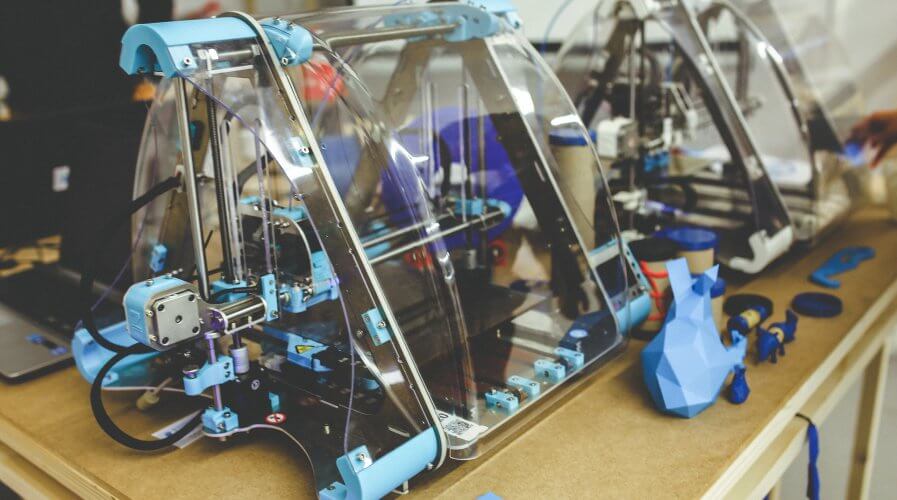

3D printing has many applications in the industrial world | Source: Pixabay

Industrial 3D printing to pick up in APAC – new study

UNDERSTANDING the true potential of 3D printing isn’t easy when you look the how consumers around you have responded to the device. However, it’s a different story altogether when it comes manufacturers in the industrial space.

Just last year, Siemens and HP announced a partnership that would advance 3D printing for product development and industrial production.

Together, they launched a new software module that enables customers to combine design, optimization, simulation, preparation of print jobs, and inspection processes in a managed environment.

In November, GE also launched a 3D printing machine that can provide manufacturers of large parts and components with a scalable solution that can be configured and customized to their own specific industry applications.

In short, GE’s device can print “large complex metal parts for aviation, automotive, space, and oil and gas industries”.

Obviously, 3D printing for industrial use is picking up – and doing well.

WATCH: Here's how 3D printing is spurring revolutionary advances in manufacturing and design. @milesobrien reports: https://t.co/yOEXaexWPw pic.twitter.com/aqzApOA4os

— PBS NewsHour (@NewsHour) March 23, 2018

According to a ReportsnReports.com study, the industrial 3D printing market is expected to reach US$5.66 billion by 2023 from US$1.73 billion in 2018 at a CAGR of 27.21 percent during 2018 and 2023.

This growth will be driven by the evolution of 3D printing from developing prototypes to end-use parts production, ease of developing customized products, developments in existing industrial 3D printing materials market, government investments in 3D printing projects, and improvement in manufacturing efficiency.

The online market research company pointed out that the industrial 3D printing market in the Asia Pacific (APAC) region is expected to witness the highest CAGR during the forecast period.

APAC is the fastest-growing market for automotive and printed electronics industries and offers new market opportunities for industrial 3D printing. Tooling and robotics are the major applications driving the market for industrial 3D printing in APAC. Japan and China are the major contributors to this market.

Although much of the growth is expected from Asia, there are hardly any Asian companies among the top 3D industrial printers cited in the report.

However, some promising Chinese companies such as UnionTech and Hunan Farsoon High Technology are making headway in the field and might soon join the ranks of 3D Systems Corporation, Stratasys Ltd, Sculpteo, and Voxeljet AG.

According to the report, the growth of the industrial 3D printing market is driven by the reduction in the manufacturing cost and process downtime, decrease in lead time due to lesser manufacturing steps, and ability to produce multiple individual parts which support customized tools and machinery parts production.

Further, the evolution of industrial-grade materials has helped expand the application area of industrial 3D printing methods into niche sectors, such as printed electronics, and energy and power sector.

Strong demand from aerospace and defense, automotive, and healthcare industries; growth of industrial 3D printing service sector; and government investments in 3D printing projects are also driving the growth of the industrial 3D printing market.

Marketsandmarkets.com found that industrial 3D printing holds great potential in the printed electronics industry as it provides the opportunity to engineers to develop objects with complex internal structures, which otherwise would be difficult to produce using traditional methods.

The growing adoption of industrial robotics in the printed electronics industry is driving the industrial 3D printing market for the robotics application as it is used to develop robot arms, grippers, and body parts.

Common electronic materials including conductor, dielectric, resistor, and semiconductor inks can be processed to print sensors, antennae, shielding transistors, solar cells, light-emitting diodes, and other active and passive components.

The industrial 3D printing market for materials expected to grow at highest CAGR during the forecast period.

However, limited availability and the high cost of materials, difficulties associated with the use of 3D printing software, and lack of standard process control are the key restraining factors for the market growth.

What’s next for 3D printing? Maybe helping robots become more human, according to Harvard – whose scientist have come up with a 3D printing ink that allows robots to have the sense of touch.

.@Harvard researchers have created a #3Dprinting ink that could allow #robots to have the sense of #touch! Continue reading to find out how the ink works: https://t.co/sgy37t57uT pic.twitter.com/0tc3luM6KP

— Autodesk Fusion 360 (@adskFusion360) March 12, 2018

READ MORE

- Strategies for Democratizing GenAI

- The criticality of endpoint management in cybersecurity and operations

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications

- How Japan balances AI-driven opportunities with cybersecurity needs

- Deploying SASE: Benchmarking your approach