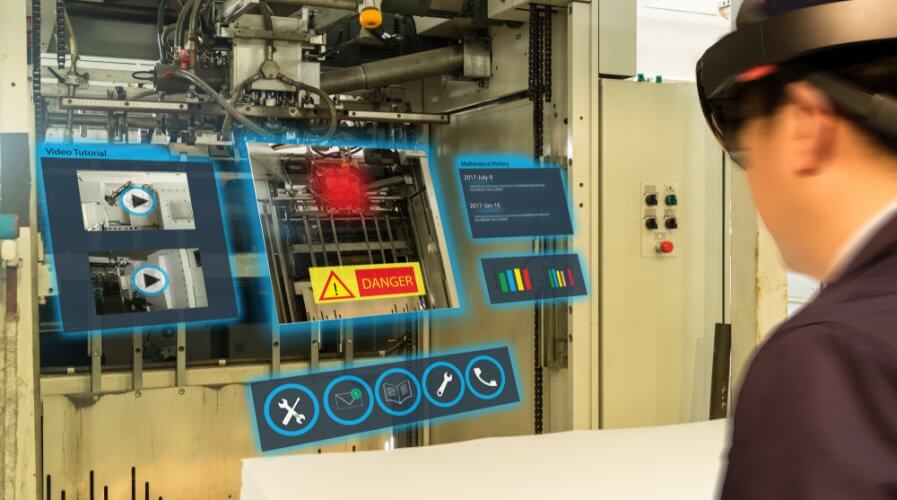

Here’s why AR is key to training in manufacuring facilities. Source: Shutterstock

Here’s how AR can help manufacturers provide better training

TRAINING is critical to most jobs today be it blue-collar or white. However, as employees expect better, smarter, and more importantly, digital experiences, businesses need to give more thought to how they deliver any kind of training or instruction.

In most cases today, augmented reality (AR) can help make training exciting and effective at the same time, elevating employee experiences and boosting retention.

Academic research suggests that AR transforms the way information is consumed as it overlays digital content and analytics onto real-world systems and applications, boosts learning, and helps shorten the learning curve by “showing employees” how to do something, in real-time.

Practically speaking, AR-based training is best suited to workers who need to learn on-the-go and lends itself best to training that requires a high degree of precision.

Since AR makes it possible to provide training visual, auditory, and kinesthetic cues during training, it can cater to a wide variety of use cases, be it in the factory or in other environments.

Experts suggest that AR is an incredibly efficient tool when it comes to providing employees with feedback, in real-time about a certain process — even remotely. This is one of the key benefits of investing in AR-based learning tools.

AR also reduces safety risks as employees can get access to robust instructions instead of fiddling around with machinery referring to traditional manuals that don’t provide visual cues or even specific instructions.

Ultimately, AR makes it easy for workers to navigate through factories and warehouses for a spare part, tool or machinery and allows them to become more efficient.

Recently, in an interview, Lockheed Martin Augmented and Mixed Reality Principal Investigator Shelley Peterson revealed that the organization uses AR to quite an extent.

Peterson explained that the building of space crafts requires the company’s engineering teams to interpret a lot of data. “And that interpretation takes time. When you can place data spatially, there’s just a significant advantage. It removes so much of the interpretation.”

The company’s technicians along and quality engineers use AR on a daily basis, provide feedback on what AR can be used for, and sometimes creating their own AR content for internal use.

At the end of the day, manufacturing companies stand to gain significantly by using AR tools in training scenarios and use cases.

READ MORE

- Strategies for Democratizing GenAI

- The criticality of endpoint management in cybersecurity and operations

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications

- How Japan balances AI-driven opportunities with cybersecurity needs

- Deploying SASE: Benchmarking your approach