(Source – Huawei)

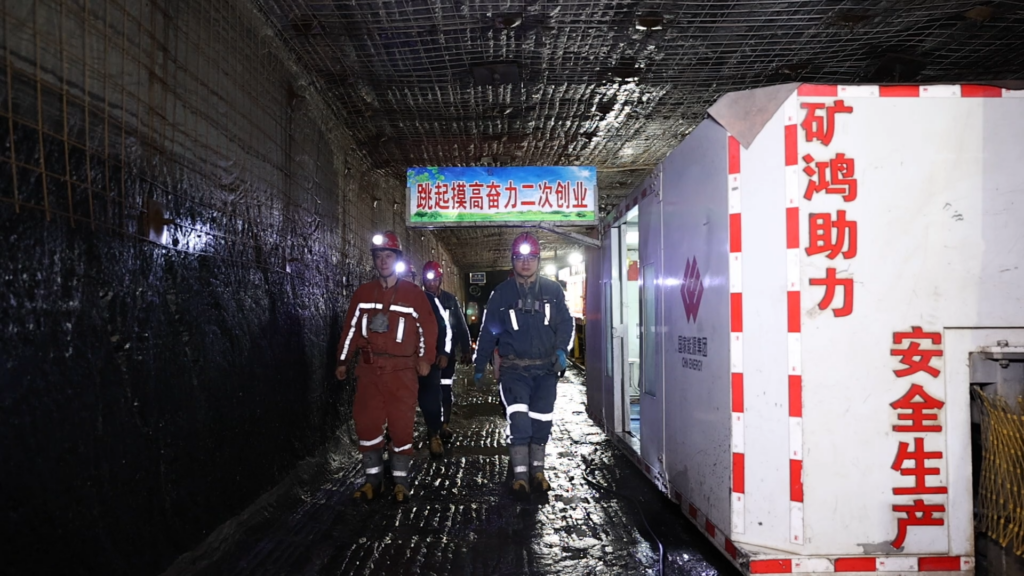

Huawei is using 5G and AI for safer smart mining

- China has found recent practices in smart mining through an Industrial Internet Architecture embedded with 5G, artificial intelligence (AI)

- Huawei’s MineHarmony assists mining businesses in collecting data online, in real-time, and synchronizing the data with equipment and systems across scenarios

The mining industry is undergoing many exciting changes, and we are already benefiting from new technology and its effects on sustainability, productivity, and safety. However, this does not imply that mining won’t face challenges in the future. There will be challenges to overcome, such as learning how to use new technology or adjusting to a changing planet. Furthermore, mining has always been a dangerous job, but smart mining technologies aim to make it safer than ever before, which has increased the mining industry’s attention to innovative solutions to some of the major problems it confronts today.

Let’s talk about the main problems the mining industry is currently dealing with.

Mining operations are going deeper and deeper to produce the minerals humans need. Numerous issues arise from this, particularly in terms of worker safety. The environment is riskier and the chance of rock fracturing increases the deeper the mine. This has increased the pressure on mining innovators to develop solutions to maintain stable mines and safe workers.

There have been numerous tragic mining accidents worldwide just in the last month.

China, a country with 5,300 mines and 1.3 trillion tons of proven coal reserves, may have found recent practices in smart mining. All comes through an Industrial Internet Architecture embedded with 5G, artificial intelligence, and basic research to be thought-provoking in pursuing safe, intelligent, efficient, and environmentally friendly mining.

In fact, production processes, including mining, tunneling, and transportation, have all been impacted by 5G and AI.

(source – huawei)

The challenges of coal mining operations

Dust cannot be avoided in the fully mechanized mining face, where the working conditions are harsh. Although remote-controlled mining has gained industrial acceptance, accurate and real-time visualization is a significant obstacle. Today, wireless backhaul of HD films with hundreds of channels and uplink bandwidths up to over 1 Gbit/s are supported by the ultra-high bandwidth of 5G networks and the inverted uplink-downlink timeslot configuration technology. Using AI technology, a panoramic image is created by stitching together several individual photographs.

Additionally, the dust-filtering algorithm ensures that real-time HD films of moving shearers may display the working environment around shearers within a radius of 20 meters, even when covered in dust and mist.

As a result, 5G networks’ low latency makes it possible for people working below to remotely manage office operations, ensuring remote and accurate management of mining equipment.

The most challenging and hazardous coal mine operation is underground tunneling. More than 40% of coal mine accidents are caused by tunneling-related mishaps. Underground safety in conventional mines depends on manual labor, such as team leaders watching over their subordinates. In a field where more than 50% of tunneling accidents are related to human error, it becomes extremely unlikely to thoroughly identify and mitigate risk elements. Real-time warnings could be set off when violations and quality issues are discovered with 5G backhauling real-time onsite video while AI algorithms track and detect subsurface activity, ensuring operational safety from a technological aspect.

(Source – Huawei)

Smart mining to address pain points

Then came MineHarmony, an operating system that standardized device languages and unsupervised enabled inspections. The system supports devices of all sizes and employs unified protocols to enable data sharing, machine-machine connections, ambient awareness, and human-machine connections.

The command and dispatch personnel monitor mining operations from above ground and intelligently dispatch tasks in real time, allowing safer and more productive production based on complete real-time data. For instance, the command and dispatch center can quickly coordinate evacuations, shut down mining equipment, and ventilate the site after detecting issues like gas overflows. This increases the effectiveness of the emergency response.

With advances in physics, mathematics, and other fundamental research areas, 5G + AI will be used in more mining scenarios. AI algorithms will synthesize expert knowledge to relieve people of dangerous, challenging, and repetitive jobs. For instance, AI-based video analysis will help intelligently detect the drilling depth during operations for pressure release and rock burst avoidance, providing traceable quality and controllable processes while safeguarding the underground production environment.

According to Ge Shirong, president of China University of Mining and Technology and Beijing Academician of the Chinese Academy of Engineering, the industry requires an operating system that enables pervasive interconnection for coal mines.

“For equipment, we need to continue improving and promoting dedicated operating systems such as Mine-Harmony to unify data access standards and specifications. Intelligent coal mining has been promoted rapidly in China. Digital technology is key to helping coal mines achieve this goal, but still has a long way to go,” he explained.

READ MORE

- Safer Automation: How Sophic and Firmus Succeeded in Malaysia with MDEC’s Support

- Privilege granted, not gained: Intelligent authorization for enhanced infrastructure productivity

- Low-Code produces the Proof-of-Possibilities

- New Wearables Enable Staff to Work Faster and Safer

- Experts weigh in on Oracle’s departure from adland