Indias Prime Minister Narendra Modi shakes hands with Micron Technology CEO Sanjay Mehrotra during a visit to the National Science Foundation in Alexandria, Virginia, on June 21, 2023. (Photo by Mandel NGAN / AFP).

India anticipates first homegrown chip from Micron by December 2024

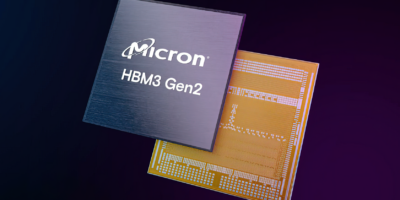

- The upcoming facility by Micron, set to be the inaugural semiconductor plant in India, will produce the first locally made semiconductor chip in precisely one year.

- Micron will focus on the assembly and testing of DRAM and NAND products to cater to the demands of both domestic and international markets.

- The questions will be whether Micron can meet its deadline, and how many other manufacturers will follow it.

Not long ago, the Minister of Electronics and Information Technology in India, Ashwini Vaishnaw, announced that a semiconductor assembly and testing facility, valued at US$2.7 billion, is being built in Gujarat by US memory chip giant Micron Technology. The new facility will be completed in stages, but the initial phase is expected to be operational by late 2024. In other words, by December 2024, India is set to produce its first domestically manufactured chips with Micron.

“In December 2024, we should see the first made-in-India chip coming out of the Micron plant. This has given huge momentum and confidence to the entire semiconductor industry worldwide,” Vaishnaw told Forbes India in September this year. The Minister noted that Micron’s plan had triggered inquiries worldwide and that in the following months, India has received more semiconductor proposals.

“India has excellent expertise in design already. Skill and talent are part of our semiconductor policy, which is succeeding very well. It’s a very systematic way we are working with the industry to get this skill,” he added. Micron’s second phase of the facility is slated to commence in the latter half of the decade, creating up to 5,000 new direct jobs.

Ashwini Vaishnaw, the Union Cabinet Minister for Railways, Communications, Electronics and Information Technology speaks during a press conference at a railway station in Srinagar on March 25, 2023. (Photo by TAUSEEF MUSTAFA / AFP).

Micron specializes in producing Dynamic Random Access Memory (DRAM) and NAND products. DRAM serves as the primary memory or RAM in devices, temporarily storing data and instructions for processor execution. NAND is a non-volatile storage device retaining data without power, similar to a portable flash drive.

Of the comprehensive investment of US$2.75 billion, Micron is set to contribute up to US$825 million across the two project phases, with the remaining assets to be sourced from both central and state governments. The Indian central government will provide 50% fiscal support for the overall project expenditure, and the state of Gujarat will offer incentives equivalent to 20% of the total project cost to the memory chipmaker.

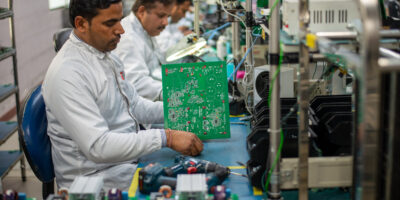

The inaugural high-end semiconductor fabrication facility set to emerge in India will feature complete automation, covering hardware and system processes from assembly to testing. Inventory and warehouse storage will be automated for efficiency. Micron plans to implement advanced process controls and smart manufacturing solutions in the 1.4 million-square-foot facility, including 500,000 square feet of clean room space.

While the facility is expected to be operational by the end of next year, Micron will gradually increase capacity based on global demand.

Besides Micron, how is the Semicon India program doing?

Supported by the Indian government’s US$10 billion ‘India Semiconductor Mission‘ aimed at boosting the country’s semiconductor manufacturing ecosystem, potential manufacturers have, since December 2021, been able to access financial incentives covering up to 50% of costs of marketing, packaging, outsourced assembly, testing units, and development and deployment.

Anil Agarwal, the chairman of Vedanta, a British mining and metals group, has said people should expect “Vedanta made-in-India chips” by 2025. Agarwal revealed in late July that there are ongoing discussions with three companies for distinct partnerships in foundry, chips, and packaging/testing for Vedanta semiconductor unit in India. In an exclusive conversation with Mint, Agarwal expressed optimism that these collaborations should materialize within the next few months.

Vedanta has chosen Dholera, an undeveloped area in Gujarat, as the site for India’s first ‘semicon city,’ an area comparable in size to Singapore. Recently, AMD, a US-based semiconductor design company, opened its largest global design center, covering 500,000 square feet, in Bengaluru.

https://x.com/AshwiniVaishnaw/status/1729538976447336898?s=20

This facility, encompassing 60,000 sq ft of research and development (R&D) labs, will house 3,000 engineers focusing on semiconductor technology design and development, such as 3D stacking, AI, and machine learning. Initially, with four operational floors for around 1,000 employees, the facility constitutes 25% of AMD’s total US$400 million investment, as previously stated by Mark Papermaster, the company’s chief technology officer.

READ MORE

- Safer Automation: How Sophic and Firmus Succeeded in Malaysia with MDEC’s Support

- Privilege granted, not gained: Intelligent authorization for enhanced infrastructure productivity

- Low-Code produces the Proof-of-Possibilities

- New Wearables Enable Staff to Work Faster and Safer

- Experts weigh in on Oracle’s departure from adland