David Irecki, Boomi’s Director for Solutions Consulting, discusses why legacy application modernization is a game-changer for the manufacturing sector.Source: Shutterstock

Boomi: How automation helps the manufacturing sector thrive in adversity

- David Irecki, Boomi’s Director for Solutions Consulting, discusses why legacy application modernization is a game-changer for the manufacturing sector.

- He also shared how integration platforms can help manufacturers remain resilient in adversity.

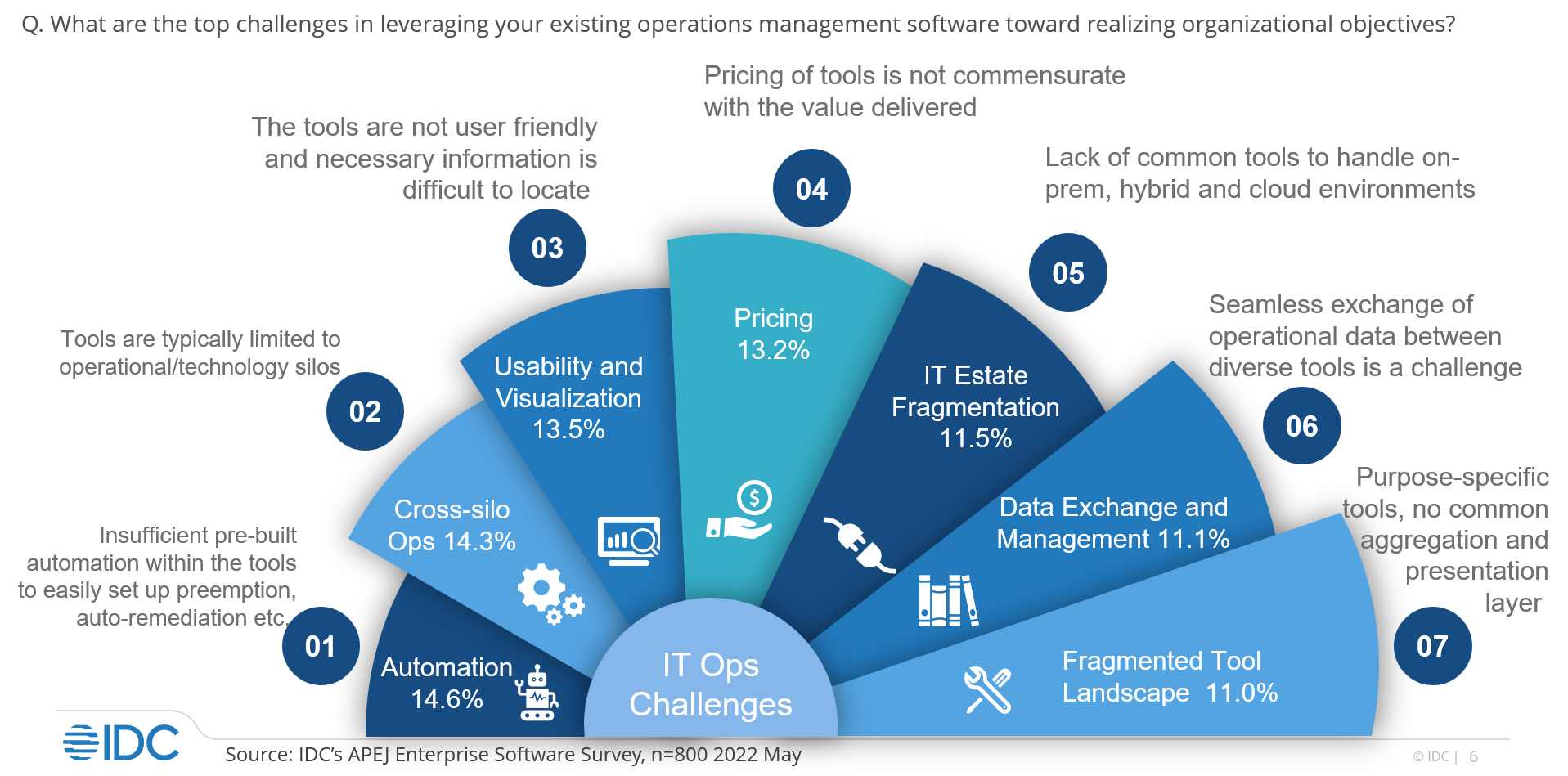

Automation in the manufacturing sector has revolutionized the way products are made, from the earliest days of mechanization to the advanced robotics and machine learning technologies we have today. However, many businesses are still grappling with their automation efforts. In a 2022 report by IDC on IT Operation Challenges in the Asia Pacific, automation was identified as the biggest concern by enterprises.

The report stated that 14.6% of businesses needed more automation with pre-built software and could not set up pre-emption and auto-remediation. The upside is that regional enterprises are looking to scale their automation initiatives, and the voracious appetite is driving automation across diverse horizontal and industry-specific business processes.

That is also why automation has steadily risen to the top of enterprise priorities over the last few years. But many business and IT leaders need help with a juggling act: build the new while keeping the old running smoothly and reliably. What’s making this juggling act even more difficult? Being stuck with the complexity and technical debt that comes with legacy middleware technology.

Tech Wire Asia had an opportunity recently to discuss with an executive from Boomi, a leading provider of cloud integration and workflow automation solutions, on how automation can help businesses thrive and remain agile in the face of current disruptions. David Irecki, Boomi’s Director for Solutions Consulting, also discussed why legacy application modernization is a game-changer for manufacturing.

This interview has been edited for length and clarity.

TWA: How has Boomi evolved since it first entered the market?

David Irecki, Boomi’s Director for Solutions Consulting,

Boomi is an integration platform, also known as an IPaaS, that is based in the cloud. Our platform basically allows companies to integrate applications, databases, partners, and customers easily. We’ve been in the market for over 20 years and have over 20,000 customers, the largest of the integration vendors out there.

For us, it’s been a journey and an evolution with our customers, not just in manufacturing, but we have customers all over the spectrum, from education to FSI to retail. Integration is ubiquitous; every company needs it, whether they know it or not.

TWA: In terms of automation, how would you describe the changes within the manufacturing sector over the years?

For Asia Pacific, it is not just with manufacturing. Many industries are still undergoing significant transformation due to the remnants of Covid-19, changes in the global economy, or technological advances. If we look at manufacturing specifically, they are an example of legacy modernization.

Many organizations still have legacy on-premise applications and may still have data on mainframes. So more of them are looking at how they modernize those systems, more so around ERP modernization, and how they move data between those systems as they update. That’s a massive thing for us.

The automation side of the coin plays a significant factor as well. Take B2B, for instance – a lot of the process is manual, like the processing of invoices and orders via email, FTP, or other means.

Many customers are coming to understand how we can automate those processes. But in general, there is quite a broad spectrum of use cases, depending on the company’s maturity or even the country.

TWA: Regarding integrating applications and data in the enterprise, what issues do companies need help with today?

Yes, many companies saw legacy systems and processes as a barrier, but part of that was also data silos. Data is an essential part of a business because if you can receive and analyze that data, you can translate it into precious business intelligence.

IDC Reveals Asia Pacific Enterprises’ Top 7 IT Operations Challenges With Their Existing Operations Management Software – 2022 Jul -F-1

But data silos, which are essentially a collection of data held by one group that is not quickly or thoroughly accessible by other groups in the same organizations, lead to several processes. After all, there is a cost to using data, and behind the glamor of powerful analytical insights is a backlog of tedious data preparation.

It’s not only about breaking down those data silos but also about the collaboration between teams since many do not communicate with each other. Then, move with the goal of integration in mind. Each progressive step should also build toward an integrated platform for your enterprise data. You don’t want to recreate a whole new set of silos, albeit with advanced capabilities.

To do this, you’ll need support from the highest level. Getting the buy-in of those stakeholders is critical because they control the budget, understand the internal politics, and can facilitate the necessary. After all, organizational changes will be inevitable as you progress in using data in operational and strategic applications.

TWA: How does implementing modern tech help manufacturers leverage data analytics to improve operational efficiency for their logistics?

The majority of these businesses are trying to respond to increasing customer demands. And they’re trying to do that faster while optimizing those processes and trimming costs. Whether they’re looking at legacy modernization or supply chain efficiency, or supporting B2B channels, they’re looking at different ways that technology can help them achieve those outcomes quicker and less costly.

And in doing so, it opens a lot of new opportunities for the business. Especially with many of our customers when they use tools to analyze their data. Allowing a single, 360-degree view makes it easier for companies to gather those insights and share that data up and down the supply chain,

TWA: How can integration platforms help the manufacturing sector remain resilient and thrive amid disruptions and uncertainty?

Many countries in Asia do not solely rely on local talent but also foreign talent as part of their businesses. When their foreign town talent left over the Covid-19 period, it’s been tough to plug those gaps again.

And that’s where an integration platform can automate some of those processes that were done by manual labor in the past, so you can fill those workforce gaps with automation. That’s one way that has really stuck out with me recently.

TWA: The costs and failures of previous attempts at big-bang modernization approaches are well-known. How can a company overcome such obstacles?

I always say start small. We see plenty of use cases where businesses that create small prove out the return, and then very quickly, the company grows from there.

TWA: When it comes to integrating applications and data in the enterprise, what are the issues companies are struggling with today? How do you recommend they address these challenges?

Data is always a prevailing theme. We did some research a couple of years ago within our customer base and understood that over 60% of data was dark within an organization. In the first place, you need to know what you’re integrating and if it is the correct data.

That is a problem where technology like data catalogs can assist because you can catalog that data, understand it, and potentially use data preparation tools to clean it up. The next is around connectivity. Yes, and so many vendors like ourselves, we have a wide variety of random connectors and too many applications for your Salesforce, SAP, NetSuite, etc.

That is where we have taken on the task of abstracting and, from a friendly, simple user interface, how to connect to that application. But it’s a familiar story across all of our customers. It’s all about understanding your data, relating to it, and then understanding your use case.

Is it complex enough that you require central IT to do it? We have more and more customers that are looking at the low code capabilities of Boomi. For example, if we use Workday in HR, and a Workday consultant understands integration, why can’t we provide them access to the Boomi platform and let them build the HR onboarding use case and leave them from central IT?

Any near/long-term outlook regarding integration and automation for enterprise?

The low code approach to integration continues to resonate in the market. A recent IDC report said that by 2024, 50% of enterprises will be training and supporting business users to automate their processes using low-code tools. So that resonates, and the skill shortage will still be part of that.

Automating and integrating data will be seen as a means to increase productivity, even though you don’t have that labor. I also think the democratization of integration and automation across the business will also be critical. Because by offering data to other parts of the company or offering integration processes, they can build things they never thought they’d be able to before. IDC has said that they would see a 20% revenue increase.

READ MORE

- Safer Automation: How Sophic and Firmus Succeeded in Malaysia with MDEC’s Support

- Privilege granted, not gained: Intelligent authorization for enhanced infrastructure productivity

- Low-Code produces the Proof-of-Possibilities

- New Wearables Enable Staff to Work Faster and Safer

- Experts weigh in on Oracle’s departure from adland